Why Your Model Train Keeps Derailing — And How to Fix It

Sick of derailments? Learn the most common reasons model trains go off-track — and how to fix them for good.

Few things are more frustrating for a model railroader than watching your engine or rolling stock repeatedly derail — especially when you’re not sure why. Whether you’re just getting started or returning to the hobby after a break, derailment issues can quickly sap the fun out of your layout.

Fortunately, most derailments can be traced to a small set of predictable causes. This guide will walk you through the most common reasons your model train keeps derailing and show you how to fix them step-by-step.

Use this guide like a checklist. Fix the most common (and easiest) issues first, then move on to more advanced troubleshooting if needed.

Check Your Track Alignment

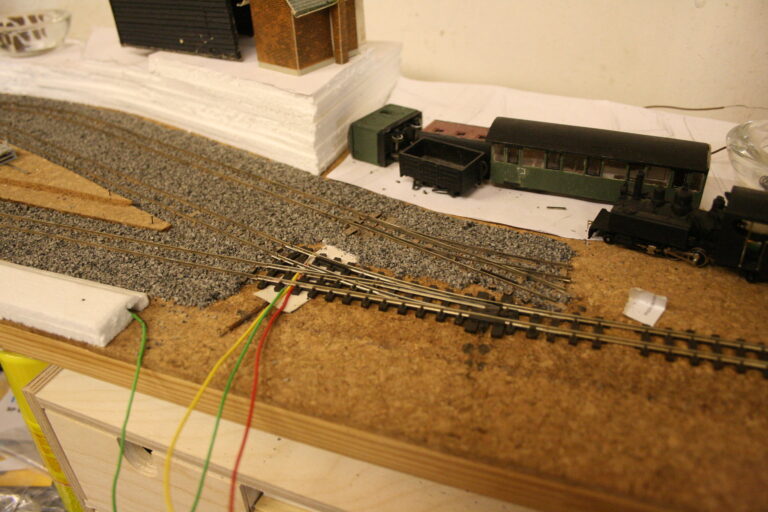

Misaligned track is the most common cause of derailments — especially on curves, turnouts, and at rail joins. Even a small kink or dip can throw wheels off.

What to Look For

- Gaps between rail joints

- Vertical dips or humps

- Misaligned rail ends on curves

- Sections that don’t lie flat or securely on the surface

How to Fix It

- Use a straightedge or metal ruler to check for level and alignment

- Ensure sectional track is securely snapped or soldered together

- On curves, confirm the arc is smooth and consistent

- Check that the roadbed is level and stable before laying track

If you’re new to track laying, read Track Wiring for Beginners: A No-Fear Visual Guide for a solid foundation.

Inspect Wheel Gauge

Wheel gauge refers to the distance between the inside edges of the wheels. If it’s too wide or too narrow, the wheels won’t sit correctly in the rails.

What to Look For

- Wheels that wobble or hunt side-to-side

- Cars that derail in the same spot regardless of train position

- Trucks that roll poorly or resist turning

How to Fix It

- Use an NMRA gauge tool to measure wheel spacing

- Adjust the wheels using a wheel puller or by gently sliding them into spec

- Replace trucks on out-of-spec cars

Buy an NMRA HO Standards Gauge

Clean Dirty Rails and Wheels

Dust, oxidation, and oil reduce traction and electrical contact, leading to stalling or derailing.

What to Look For

- Visible grime or dark streaks on the rails

- Engines that stall or stutter

- Squealing or slipping sounds

How to Fix It

- Wipe rails with a soft cloth and isopropyl alcohol or a dedicated track cleaning solution

- Use a wheel-cleaning tool or Q-tip with alcohol for engine wheels

- Avoid sandpaper or abrasives that can scratch track

For beginner-friendly, low-maintenance track, see Best Track Packs for Beginners: Expand Without Overcomplicating.

Slow Down on Curves and Turnouts

Running trains too fast through curves or switches is a guaranteed way to cause derailments.

What to Look For

- Trains derail only at higher speeds

- Cars tip outward on curves

- Lightweight cars get whipped around

How to Fix It

- Reduce speed overall, especially through curves

- Ease into curves gradually rather than braking hard

- Avoid long, light cars directly behind heavy engines

Adjust Trucks and Couplers

Trucks that are too tight or too loose can cause binding, especially on curves. The same goes for couplers that don’t pivot correctly.

What to Look For

- Cars that resist turning on curves

- Stiff or droopy couplers

- Inconsistent tracking

How to Fix It

- Loosen truck mounting screws slightly to allow free swivel

- Clean flash from plastic trucks

- Upgrade to high-quality magnetic couplers

Match Radius to Car Length

Longer cars don’t do well on tight radius curves. The tighter the curve, the more risk of derailment.

What to Look For

- Derailments only occur on curves

- Long cars “pop” off mid-curve

- Couplers bind or jackknife

How to Fix It

- Use 22” radius curves or larger for full-length cars

- Stick to 40-foot or shorter rolling stock on 18” curves

- Choose truck-mounted couplers when running tight curves

If space is a constraint, Simple Model Train Layouts That Won’t Overwhelm New Hobbyists offers layout ideas designed with smooth operation in mind.

Check Coupler Height and Centering

Uneven couplers or ones that don’t self-center can tug cars off the track, especially on uneven or curved sections.

What to Look For

- Couplers don’t align between cars

- Frequent derailments when coupling

- Couplers sag or stick

How to Fix It

- Use a coupler height gauge to verify correct mounting

- Shim or adjust mounting platforms as needed

- Lubricate or replace centering springs

Look for Kinks or Obstructions

Even minor damage or debris can consistently cause derailments in the same spot.

What to Look For

- Derailment at the same location every time

- Clicking or bumping noises when passing a section

- Misaligned joins or cracked rails

How to Fix It

- Run your fingertip along the rail to detect rough spots

- Inspect close with good lighting or magnification

- Replace problem track sections entirely if needed

Use Better Rolling Stock

Budget rolling stock often comes with subpar wheels, couplers, or trucks that lead to persistent issues.

What to Look For

- Only certain cars derail regularly

- Wobbling or resistance when rolling

- Poor tracking even on straight track

How to Fix It

- Replace plastic wheels with metal ones

- Upgrade trucks or swap in better couplers

- Retire problem cars that aren’t worth fixing

Still Having Trouble?

Sometimes multiple small issues stack up. If you’ve tried everything and your model train keeps derailing, simplify and isolate the problem.

- Test the train on a basic loop of track

- Swap out one car at a time to identify the culprit

- Revisit key fundamentals of operation

For a refresher, read How Do Model Trains Work? A Simple Explanation for Beginners.

Derailments don’t have to derail your hobby. A few basic tools, a methodical approach, and a little patience go a long way toward a smooth-running layout.