Can You 3D Print Model Trains? What’s Possible in 2025

From locomotives to landscape details — here’s what you can (and can’t) 3D print for model trains in 2025.

3D printing has quietly revolutionized model railroading. What was once a niche experiment has become a practical, affordable option for anyone looking to create custom components, replace hard-to-find parts, or even print entire cars or locomotives. Whether you’re building your own kitbash empire or just want to add realistic detail parts to a layout, 3D printing offers flexibility that’s hard to match.

In this guide, we’ll walk through what’s possible (and what isn’t) in 2025—from materials and machines to where to find the right files.

What Parts of a Model Train Can You 3D Print?

You can now reliably 3D print:

- Locomotive shells (especially for diesel or electric)

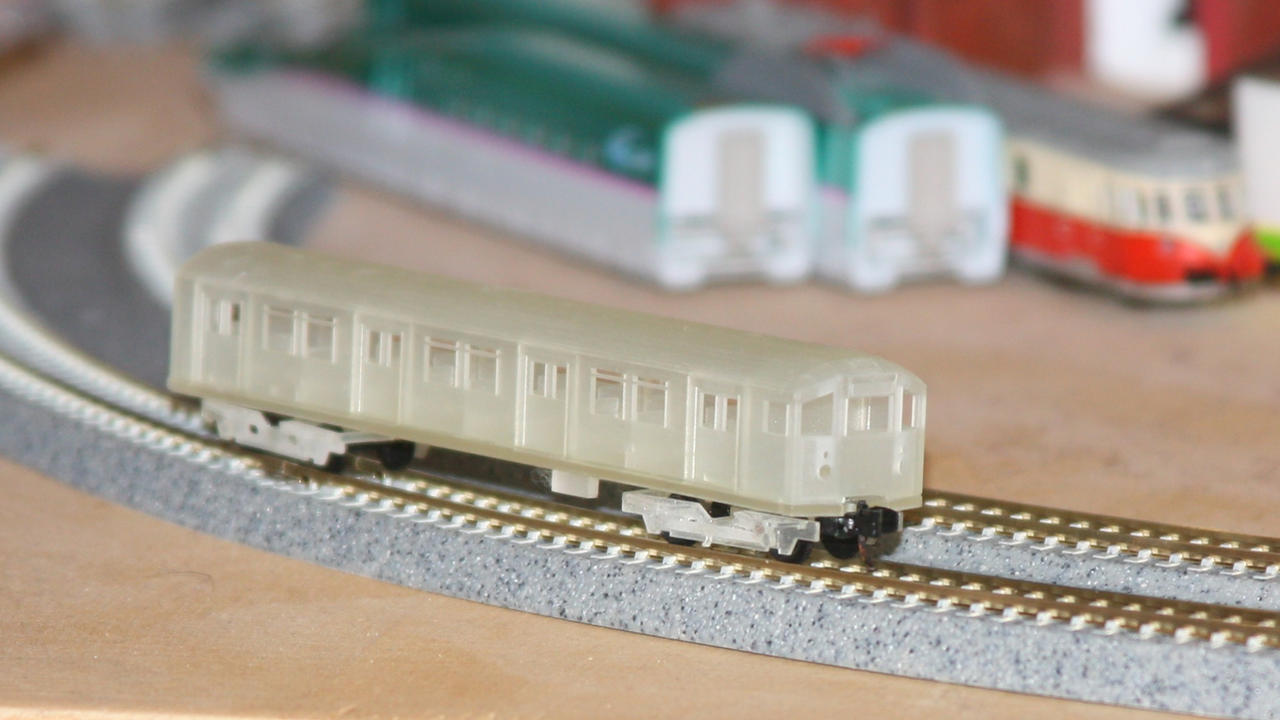

- Freight and passenger car bodies

- Detail parts like vents, horns, couplers, ladders, and grab irons

- Interior components like cab control panels or seats

- Structure kits: houses, factories, bridges, and platforms

- Scenic accessories: fences, barrels, crates, and even full-scale figures

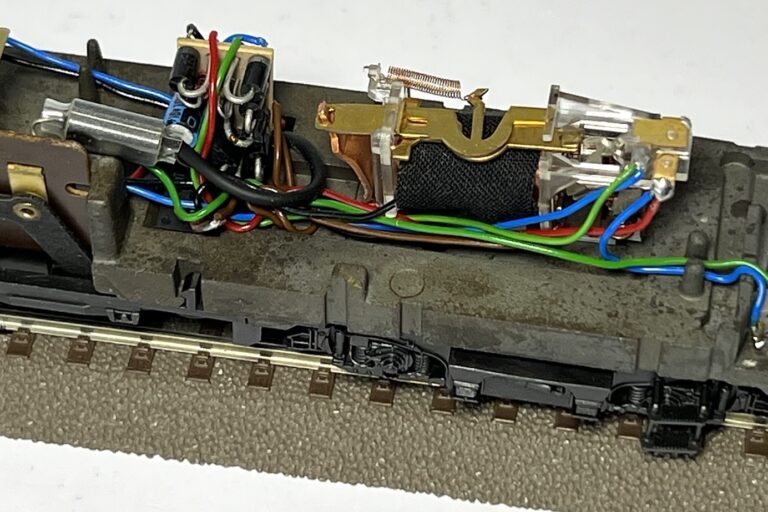

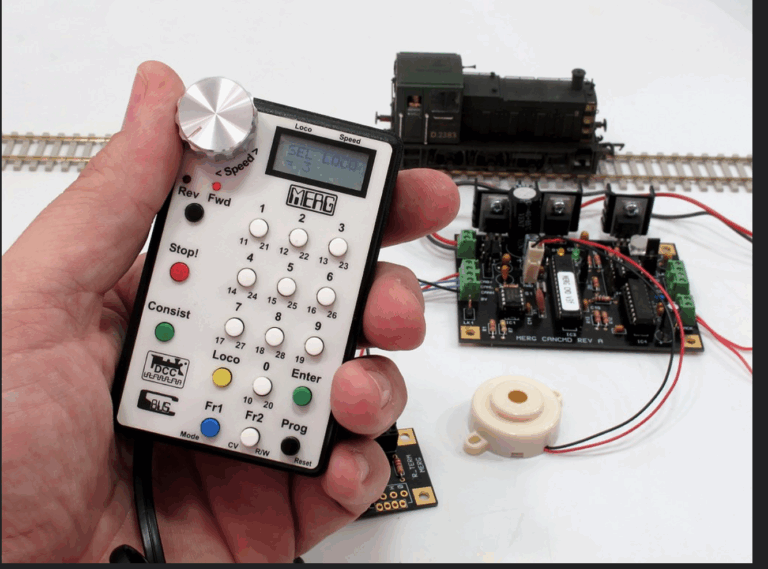

That said, you’re not going to be printing smooth-running motors, durable metal wheels, or high-precision mechanisms for DCC systems. Complex moving parts—especially anything load-bearing—should still be purchased from established manufacturers.

Resin vs. FDM Printing: What’s Better for Model Railroading?

There are two main types of home 3D printers:

- FDM (Fused Deposition Modeling): These use plastic filament to build up layers. They’re affordable, great for large prints (like buildings), and easy to operate.

- Resin (SLA or MSLA): These use UV light to cure liquid resin layer by layer. They offer much finer detail—perfect for printing small-scale parts like HO grab irons or N scale locomotive shells.

| Feature | FDM | Resin |

|---|---|---|

| Detail Quality | Medium | High |

| Print Size | Larger | Smaller |

| Material Durability | Stronger | More brittle |

| Clean-up | Easy | Messy (requires isopropyl wash and UV cure) |

| Best For | Buildings, large accessories | Locomotive shells, detail parts, small-scale |

If you’re printing for visual detail—especially in HO or N scale—resin printing is the way to go. But if you’re focused on layout scenery or structural elements, a solid FDM printer will give you more versatility with fewer headaches.

Where to Find STL Files for Model Trains

STL files (the standard 3D model format for printing) are widely available in 2025—more so than ever before. You can find free and paid designs through:

- Thingiverse: Tons of free user-created content. Some gems, lots of junk—filter carefully.

- Cults3D: Great selection of both free and premium files. Includes many scale-specific train parts.

- CGTrader: More professional models; often optimized for resin.

- Printable Scenery: High-end buildings and terrain pieces for layouts.

- Facebook groups and forums: Hobbyists often share STL files directly within model railroading communities.

Always double-check that the file matches your scale—printing an HO scale freight car in O scale by mistake is an easy way to waste hours and resin.

Which Scales Work Best for 3D Printing?

3D printing is viable at every major scale—but some are more forgiving than others:

- HO Scale: Ideal balance of size and detail. Most STL files target this scale.

- N Scale: Resin recommended. Detail parts can be fragile.

- O Scale: FDM becomes more practical here, given the larger size.

- G Scale: Perfect for outdoor FDM prints—great durability with the right materials.

As you shrink in scale, resin becomes increasingly essential for achieving usable results, especially for parts with surface detail or thin walls.

Best Materials for Printing Model Train Parts

Material matters—both for strength and finish. Here are the most common options:

- PLA (FDM): Easy to print, inexpensive, good for structures. Brittle in cold climates.

- PETG (FDM): More durable than PLA. Great for outdoor or layout-base parts.

- ABS (FDM): Strong but fussy. Requires enclosure.

- Standard Resin: High detail, brittle. Great for fine parts.

- Tough or ABS-like Resin: More impact-resistant than standard resin—ideal for shells or load-bearing parts.

- Flexible Resin: Niche, but useful for shock-absorbing components.

Paint adheres well to most materials after priming, and sanding is often required for a smooth finish, especially with FDM prints.

Recommended Printers for Model Train Hobbyists (2025)

If you’re looking to dive in, here are a few hobbyist-friendly options worth considering:

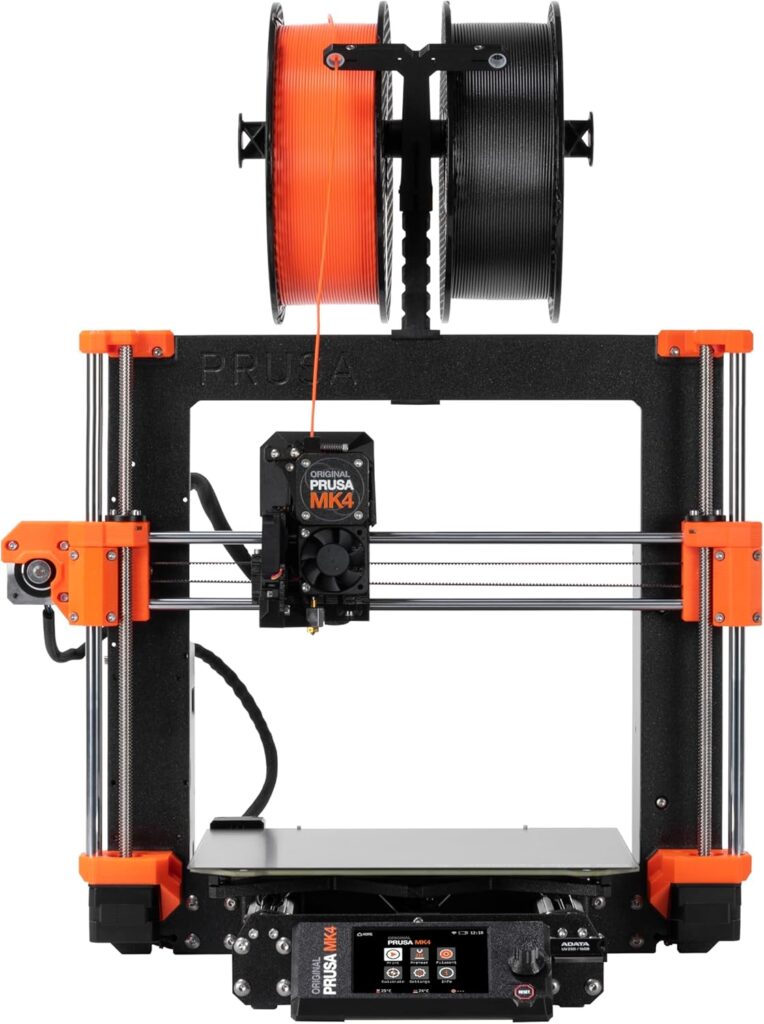

FDM Printers

- Prusa MK4 – Buy it on Amazon: A reliable workhorse with clean output and strong community support.

- Creality Ender 3 V3 SE – Buy it on Amazon: Budget-friendly and widely modded for hobby use.

Resin Printers

- Elegoo Mars 4 Ultra – Buy it on Amazon: High-resolution printing at an affordable price.

- Anycubic Photon Mono M4 – Buy it on Amazon: Great detail and build volume for HO and O scale.

Whichever printer you choose, remember to account for ventilation, especially with resin, and plan for some post-processing gear like a UV curing station and wash tank.

Limitations and Challenges

Despite the advances, 3D printing isn’t a perfect solution. You should know:

- Print lines: FDM printers often require sanding or filler to smooth surfaces.

- Warping: Large parts can warp, especially on budget machines without heated beds.

- Fragility: Thin resin prints snap easily—especially at smaller scales.

- Time: Some prints take 10+ hours, plus post-processing.

- Tolerance Issues: Parts may not fit precisely with commercial components.

Many model railroaders find it easier to print shells or details, then combine them with mass-manufactured underframes, trucks, and motors.

Is 3D Printing Cheaper Than Buying New?

It depends. If you’re printing one-off customs, replacement parts, or kitbashing scenery, the cost per part can be incredibly low—especially if you already own a printer.

But if you’re trying to replicate a ready-to-run locomotive with full detailing, weathering, and DCC integration, the time and material cost might outweigh the savings.

That said, printing can increase the value of your layout, especially if you’re creating unique or historically accurate elements. For more on collecting and value, see Are Model Trains Worth Anything? A Collector’s Guide to Value.

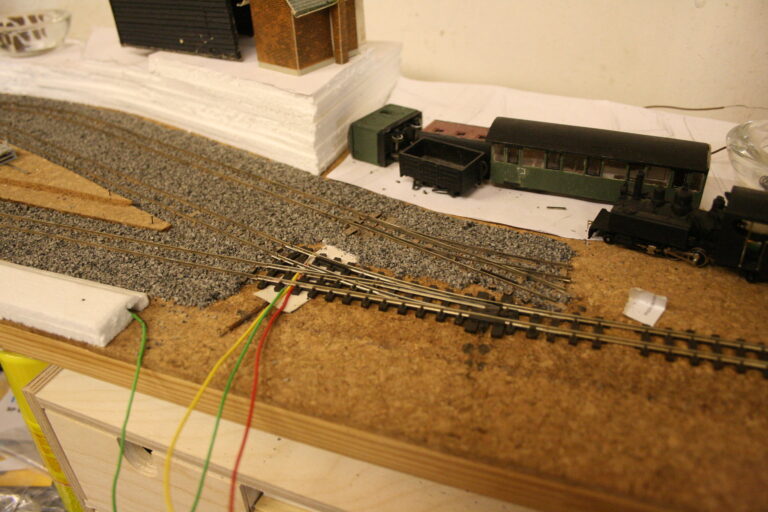

Combining 3D Printing With Traditional Modeling

One of the most exciting uses of 3D printing is for kitbashing—mixing and matching printed parts with traditional kits to create unique rolling stock or buildings. You might print a custom roof detail for a Bachmann shell or add realistic pipes and crates to a Walthers scene.

For context on the best commercial brands to blend with 3D elements, check out our breakdown of the Top 10 Model Train Brands Ranked by Hobbyists.

Final Thoughts: A Tool for Modern Model Railroading

3D printing in 2025 is no longer experimental—it’s just another tool in the model railroading toolbox. Whether you’re building from scratch or supplementing a traditional layout, printing unlocks a level of customization that hobbyists once only dreamed of.

Still, it isn’t a magic bullet. You’ll get the best results by combining 3D printed parts with commercial components, strong design files, and traditional model-building skills.

And if you’re pushing the limits of model railroading, 3D printing opens new frontiers for layout builders and tinkerers alike. For more on the cutting edge of what’s possible, don’t miss Advanced Model Train Layouts That Push the Limits of What’s Possible.